Condensate-Separator

Condensate-Separator

model KVE in a stainless steel housing

- For the continuous separation of gas/liquid mixtures

- For collection of liquids (condensate storage vessel)

- Volume can be expanded using modular technology

- Water-Trap-Cartridge (optional) prevents condensate break-through

-Made in Germany ![]()

![]()

- Certificates: ATEX 2014/34/EU

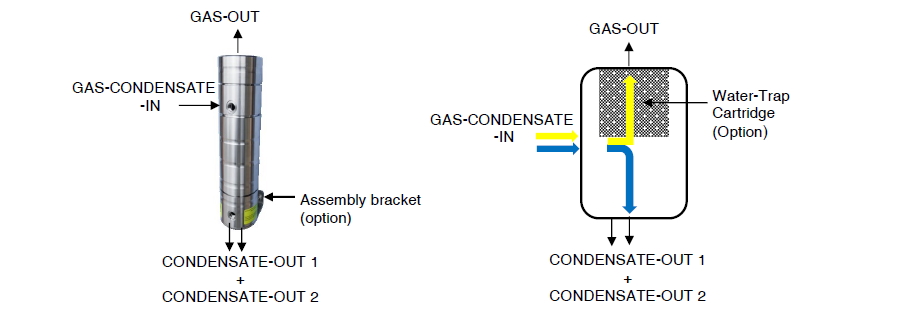

Functional description:

The Condensate-Separator model KVE is designed for continuous separation of gases and liquids. The measuring gas with percentage of condensate is lead into the Condensate-Separator via a gas input (GAS-IN). Due to the centrifugal force, the heavier condensate accumulates in the bottom of the vessel. This is drained via the condensate output 1 (CONDENSATE-OUT1).

For large condensate quantities, the condensate output 2 (CONDENSATE 2) can also be used.

The lighter measuring gas, on the other hand, is supplied to the top of the container (GAS-OUT).

A Water-Trap-Cartridge (option) can be installed. With the inside semipermeable membrane, this prevents condensate breakthrough. The membrane separates gases from water, weak acids and dust. The membrane is not suitable for condensates with liquid hydrocarbons, f.e. oils and gasoline in refining process gases.

The Condensate-Separator model KVE can be used as a condensate storage vessel.

Schematic representation:

Technical specifications:

| Scope of delivery: | Housing, Water-Trap Cartridge (option), wall assembly bracket (option) |

| Materials used: | Stainless steel, type 1.4301, FKM (O-ring) |

| Wall mounting bracket (option): | Stainless steel type 1.4301 |

| Operating pressure: | 0 - 12 bar |

| Gas flow: | 0 - 10.000 l air/h |

| Pressure drop at 1.000 l air/h: | approx. 12 mbar |

| Pressure drop at 5.000 l air/h: | approx. 30 mbar |

| Operating temperature: | +5°C - +90°C |

| Housing volume: | 750 ml |

| Housing dimensions: | Diameter 80 mm, length 300 mm |

|

Gas connections: |

GAS-IN ¼“ G - inside thread GAS-OUT ¼“ G - inside thread KONDENSAT-OUT 1 ¼“ G - inside thread KONDENSAT-OUT 2 ¼“ G - inside thread |

| Assembly: | Wall mounting with assembly bracket (option) |

| Gas explosion proof ATEX: | EX II 2G Ex h IIC Gb +5°C ≤ Ta ≤ +90°C attestation EPS 19 ATEX 2 187 U |

| Dust explosion proof ATEX: | EX II 2D Ex h IIIC Db +5°C ≤ Ta ≤ +90°C attestation EPS 19 ATEX 2 187 U |

| Language operating instructions: | German and English (included in the scope of delivery) |

| Spanish, Italian, French, Russian upon request | |

| Certificates/attestations: | 3.1 material quality certificate, NACE-MR0175-98 (on request) certificate of conformity ATEX 2014/34/EU |

| Water-Trap Cartridge (option) | |

| Water pressure membrane: | 0 - 1 bar |

| Effective filter area: | 550 cm2 |

| Diaphragm pore size: | < 0,1μm |

| Materials used: | PTFE, PP, SUN-C coating |

| Note: | The Water-Trap Cartridge is not suitable for use with aromatic hydrocarbons, e.g. oils and fuels in refinery process gases |

For operation in potentially explosive ambience:

The products can be used in explosive ambience of Zone 1, Zone 2, Zone 21 und 22.

Allowed the explosion classes IIA, IIB und IIC.

The products have no self-heating during intended operation and can be used in dependency of the maximum permissible media temperature for gases of the temperature class T6.

| Article | Article number |

|---|---|

| Condensate-Separator, model KVE, in accordance with technical specifications | KVE |

| Condensate-Separator, model KVEKAWT, in accordance with technical specifications. With integrated Water-Trap-Cartridge |

KVEKAWT |

| Options: | |

| 1 stainless steel bracket for wall mounting | MONWIWT2048 |

| Spare parts: | |

| Water-Trap-Cartridge | KAWT2048 |

| 1 O-ring FKM | OR2048FKM |

PreviousPage (no previous) - NextPage (no next) - TOP