Particle and coalescence filter

Particle and coalescence filter

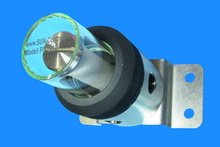

model PC 1410 E XL in a stainless steel housing

- XL housing variant

- 4 x size of standard product

- One body two filtermethodes, Separation of liquids - particle filter

- Less space is required horizontal mounting

- Self-cleaning via bypass connection

- Can be used up to 350 bar and 200°C

- Gas connections on the body sub frame

- “Easy-Filter-Change System” Simple change of filter element from the front side

It is not necessary to remove the screw connections

- To disconnect fittings is not necessary!

- Made in Germany ![]()

![]()

![]()

- Certificates: 3.1 material quality certificate, ATEX 2014/34/EU, Helium leakage tested

Functional description:

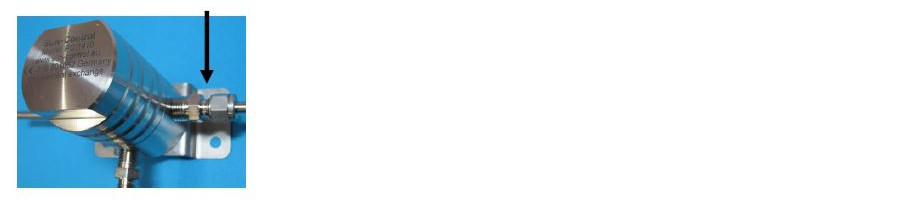

The PC 1410 model is used in the gas processing during the process gas analytics. The horizontal installation position allows less space requirement. Thanks to different filter elements, gases/liquids can be filtered (particle filter function) or liquids/aerosols can be deposited (coalescence filter function). All the gas connections have been provided for this. The filter housing can be rotated by 360° such that all the connection variants of the gas inlets and gas outlets are possible. The filter element is exchanged in a very service-friendly manner from the front side of the filter. A fussy removal of the screw connections is no longer necessary as all the gas connections are located on the firmly mounted filter base. The filter element is blocked by a retaining screw and thus cannot fall out inadvertently. The possibility of connecting a bypass is provided

Technical specifications:

| Scope of delivery: | Housing, retaining screw for filter element, O-ring FKM (Viton) assembly bracket (optional), filter element (optional) |

| Materials used: | Stainless steel type 1.4571, FKM (Viton), silicate glass (filter element), Duran glass (only D-models) |

| Wall mounting bracket (option): | Stainless steel type 1.4301 |

| Operating pressure: | 0 - 350 bar. With Duran glass 0 - 3 bar (till +25°C), 0 - 2 bar (till +80°C) |

| Gas flow: | 0 - 3000 l air/h |

| Pressure drop at 100 l air/h: | approx. 3 mbar |

| Pressure drop at 200 l air/h: | approx. 5 mbar |

| Flow rate of the liquid: | 800 l water/h at 1 bar pressure |

| Flow rate of the liquid: | 1000 l water/h at 2 bar pressure |

| Operating temperature: | - 20 °C - +200 °C |

| With Duran glass: | - 5 °C - +80 °C |

| Housing dimensions: | Diameter 75 mm, length 120 mm |

| Housing volume: | 100 ml |

| Effective filter area: | 280 cm2 |

| Gas connection 1: | ¼“ NPT inside thread (filter element exterior), on request ½” inside thread |

| Gas connection 2: | ¼“ NPT inside thread (filter element interior) on request ½” inside thread |

| Gas connection 3: | ¼“ NPT inside thread (filter element exterior) on request ½” inside thread |

| Gas connection 4: | ¼“ NPT inside thread (filter element exterior) on request ½” inside thread |

| (G-thread upon request) | |

| Assembly: | - Wall mounting using retaining bracket (optional) |

| Gas explosion proof ATEX: | EX II 2G Ex h IIC Gb -20°C ≤ Ta ≤ +200°C attestation EPS 19 ATEX 2 178 U |

| Dust explosion proof ATEX: | EX II 2D Ex h IIIC Db -20°C ≤ Ta ≤ +200°C attestation EPS 19 ATEX 2 178 U |

| Language operating instructions: | German and English (included in the scope of delivery) |

| Spanish, Italian, French, Russian upon request | |

| Certificates/attestations: | 3.1 material quality certificate, NACE-MR0175-98, certificate of conformity ATEX 2014/34/EU, Helium leakage test attestation |

For operation in potentially explosive ambience:

The products can be used in explosive ambience of Zone 1, Zone 2, and Zone 21 und 22.

Allowed the explosion classes IIA, IIB und IIC.

The products have no self-heating during intended operation and can be used in dependency of the maximum permissible media temperature for gases of the temperature class T6.

Article numbers:

Filter housing with filter top made of stainless steel:

| Article | Article number |

|---|---|

| Filter housing, material stainless steel 1.4571 (316 Ti), filter top made of stainless steel, with retaining screw for filter element, with O-ring made of FKM (Viton), without filter element, without assembly bracket | PC1410EXL |

| Filter housing, material stainless steel 1.4571 (316 Ti), filter top made of stainless steel, with retaining screw for filter element, with O-ring made of PTFE, without filter element, without assembly bracket | PC1410EXLORPTFE |

| Filter housing, material stainless steel 1.4571 (316 Ti), filter top made of stainless steel, with retaining screw for filter element, with O-ring made of FFKM, without filter element, without assembly bracket | PC1410EXLORFFKM |

| Filter housing material Hastelloy HC 22 or 1.4462-Super Duplex | on request |

Filter housing with filter top made of Duran glass:

| Article | Article number |

|---|---|

| Filter housing, material stainless steel 1.4571 (316 Ti), with filter top made of Duran glass, with retaining screw for filter element, with O-ring made of FKM (Viton), without filter element, without assembly bracket | PC1410EDXL |

| Filter housing, material stainless steel 1.4571 (316 Ti), with filter top made of Duran glass, with retaining screw for filter element, with O-ring made of PTFE, without filter element, without assembly bracket | PC1410EDXLORPTFE |

| Filter housing, material stainless steel 1.4571 (316 Ti), with filter top made of Duran glass, with retaining screw for filter element, with O-ring made of FFKM, without filter element, without assembly bracket | PC1410EDXLORFFKM |

| Filter housing material Hastelloy HC 22 or 1.4462-Super Duplex |

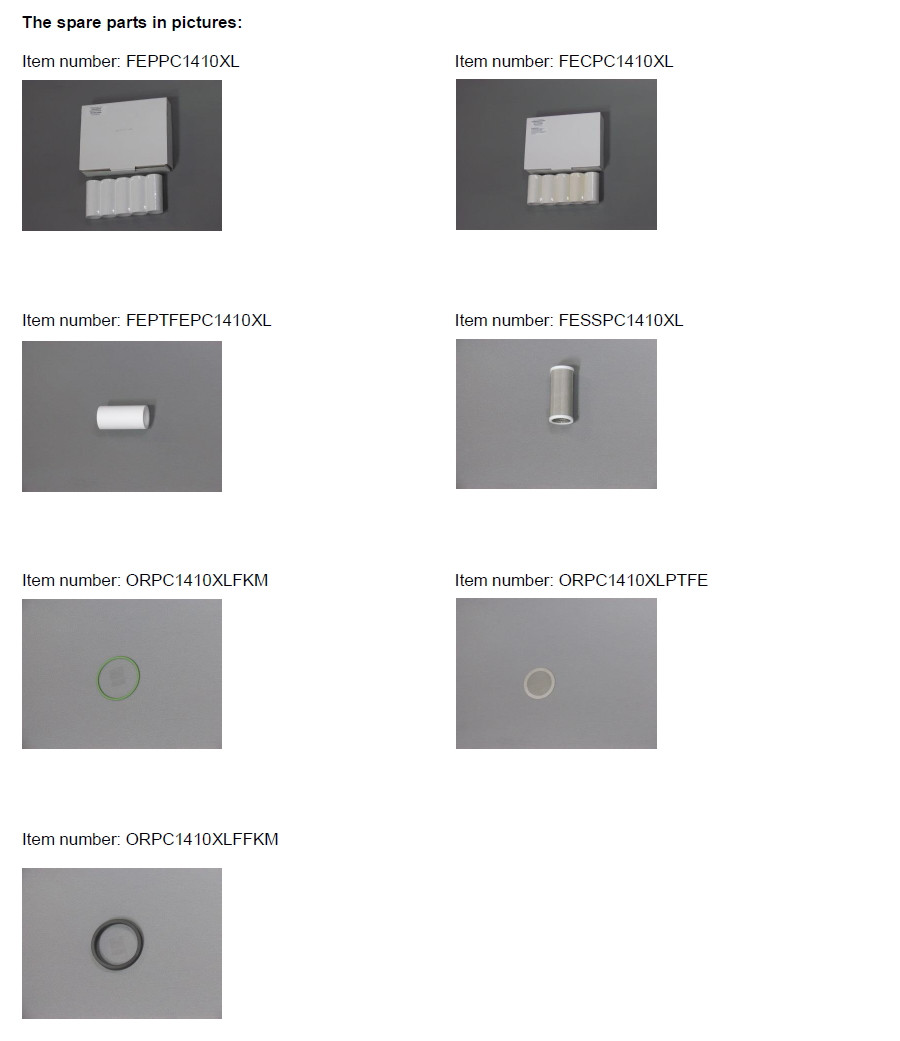

Filter elements:

| Article | Article number |

|---|---|

| Set (5 units) of filter elements for particle filtration, Material borosilicate micro glass fibres, pore size 0.1 μm, deposition rate 99.999% | FEPPC1410XL |

| Set (5 units) of filter elements for coalescence application (removal of oils and aerosoles) and particle filtration. Material borosilicate micro glass fibres, pore size 0.1 μm, deposition rate 99.999% | FECPC1410XL |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 1 μm | FEPTFE1PC1410XL |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 10 μm | FEPTFE10PC1410XL |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 25 μm | FEPTFE25PC1410XL |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 50 μm | FEPTFE50PC1410XL |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 100 μm | FEPTFE100PC1410XL |

| 1 unit of filter element for filtration of liquids made of stainless steel 1.4404 pore size 1 μm | FESS1PC1410XL |

| 1 unit of filter element for filtration of liquids made of stainless steel 1.4404 pore size 10 μm | FESS10PC1410XL |

| 1 unit of filter element for filtration of liquids made of stainless steel 1.4404 pore size 25 μm | FESS25PC1410XL |

Filter accessories and spare parts:

| Article | Article number |

|---|---|

| 1 unit of bling plug made of stainless steel, for locking the unused gas connection | VSPC1410 E |

| 1 unit of assembly bracket made of stainless steel 1.4571 for wall mounting | MONWIWAMOPC1410 |

| 1 unit of filter upper part, Duran glass | FODGPC1410XL |

| 1 unit of O-ring FKM (Viton) standard, color green | ORPC1410XLFKM |

| 1 unit of O-ring PTFE, color wihte | ORPC1410XLPTFE |

| 1 unit of O-ring FFKM, color black | ORPC1410XLFFKM |

Note:

-The standard product is equipped with FKM O-rings. For additional information about O-rings, refer to “Informations”.

-PTFE O-rings for single use only

Note: The PC 1410 model has 4 gas connections. If only two are used e.g. when using the particle filter (GAS-IN and GAS-OUT), two blind plugs will be required. If you additionally connect a bypass, only one blind plug is necessary in that case.

Please adhere to this in your next order

Ordering aid: what do I need for a complete filter?

1. Filter housing

2. Filter element

3. Assembly bracket (you can also use your own system)

4. Blind plug (the filter housing has 4 connections)

Options:

Assembly bracket made of stainless steel for wall mounting

Item number: MONWIWAMOPC1410

PreviousPage (no previous) - NextPage (no next) - TOP