Particle and coalescence filter

Particle and coalescence filter

model PC 1410 PVDF

model PC 1410 PVDF EL

- One body two filtermethodes

- Separation of liquids - particle filter

- Less space is required horizontal mounting

- Self-cleaning via bypass connection

- Gas connections on the body sub frame

- “Easy-Filter-Change System” Simple change of filter element from the front side

- To disconnect fittings is not necessary!

- Made in Germany ![]()

![]()

- Certificates: ATEX 2014/34/EU

For installation examples of the products, refer to “Installation examples of SUN-Control-Analytik products”

Functional description:

The PC 1410 model is used in the gas processing during the process gas analytics. The horizontal installation position allows less space requirement. Thanks to different filter elements, gases/liquids can be filtered (particle filter function) or liquids/aerosols can be deposited (coalescence filter function). All the gas connections have been provided for this. The filter housing can be rotated by 360° such that all the connection variants of the gas inlets and gas outlets are possible. The filter element is exchanged in a very service-friendly manner from the front side of the filter. A fussy removal of the screw connections is no longer necessary as all the gas connections are located on the firmly mounted filter base. The filter element is blocked by a retaining screw and thus cannot fall out inadvertently. The possibility of connecting a bypass is provided.

Technical specifications:

| Scope of delivery: | Housing, retaining screw for filter element, O-ring FKM (Viton) assembly bracket (optional), filter element (optional) |

| Materials used: | |

| PC 1410 PVDF | PVDF, FKM, Duran glass (upper part of the filter) |

| PC 1410 PVDF EL: | PVDF (polyvinylidene fluoride) with carbon content, electroconductive (106 Ω/mtr.) Housing colour black, FKM, Duran glass (upper part of the filter) |

| Wall mounting bracket (option): | Stainless steel type 1.4301 |

| Operating pressure with filter top made of Duran glass: |

0 - 5 bar (till +25°C), 0 - 4 bar (till +80°C) |

| Operating pressure with filter top made of PVDF: |

0 - 10 bar |

| Gas flow: | 0 - 1000 l air/h |

| Pressure drop at 100 l air/h: | approx. 5 mbar |

| Pressure drop at 200 l air/h: | approx. 10 mbar |

| Flow rate of the liquid: | 400 l water/h at 1 bar pressure |

| Flow rate of the liquid: | 500 l water/h at 2 bar pressure |

| Operating temperature: | - 5 °C - +80 °C |

| Housing dimensions: | Diameter 60 mm, height 100 mm |

| Housing volume: | 35 ml |

| Effective filter area: | 70 cm2 |

| Gas connection 1: | ¼“ G - inside thread (filter element exterior) |

| Gas connection 2: | ¼“ G - inside thread (filter element interior) |

| Gas connection 3: | ¼“ G - inside thread (filter element exterior) |

| Gas connection 4: | ¼“ G - inside thread (filter element interior) |

| Assembly: | - Wall mounting using retaining bracket (optional) - Front panel mounting using retaining bracket (optional) |

| Gas explosion proof ATEX: | EX II 2G Ex h IIB Gb -5°C ≤ Ta ≤ +80°C attestation EPS 19 ATEX 2 177 U |

| Language operating instructions: | German and English (included in the scope of delivery) |

| Spanish, Italian, French, Russian upon request | |

| Certificates/attestations: | certificate of conformity ATEX 2014/34/EU |

For operation in potentially explosive ambience:

The products can be used in explosive ambience of Zone 1 and Zone 2.

Allowed the explosion classes IIA and IIB.

The products have no self-heating during intended operation and can be used in dependency of the maximum permissible media temperature for gases of the temperature class T6.

Article numbers:

| Article | Article number |

|---|---|

| Filter housing material PVDF, filter upper part made of Duran glass, with retaining screw for filter element, with O-ring made of FKM (Viton), without filter element, without assembly bracket | PC1410PVDF |

| Filter housing material PVDF, filter upper part made of PVDF, with retaining screw for filter element, with O-ring made of FKM (Viton), without filter element, without assembly bracket | PC1410PVDFO |

| Filter housing material PVDF EL, filter upper part made of Duran glass, with retaining screw for filter element, with O-ring made of FKM (Viton), without filter element, without assembly bracket | PC1410PVDFEL |

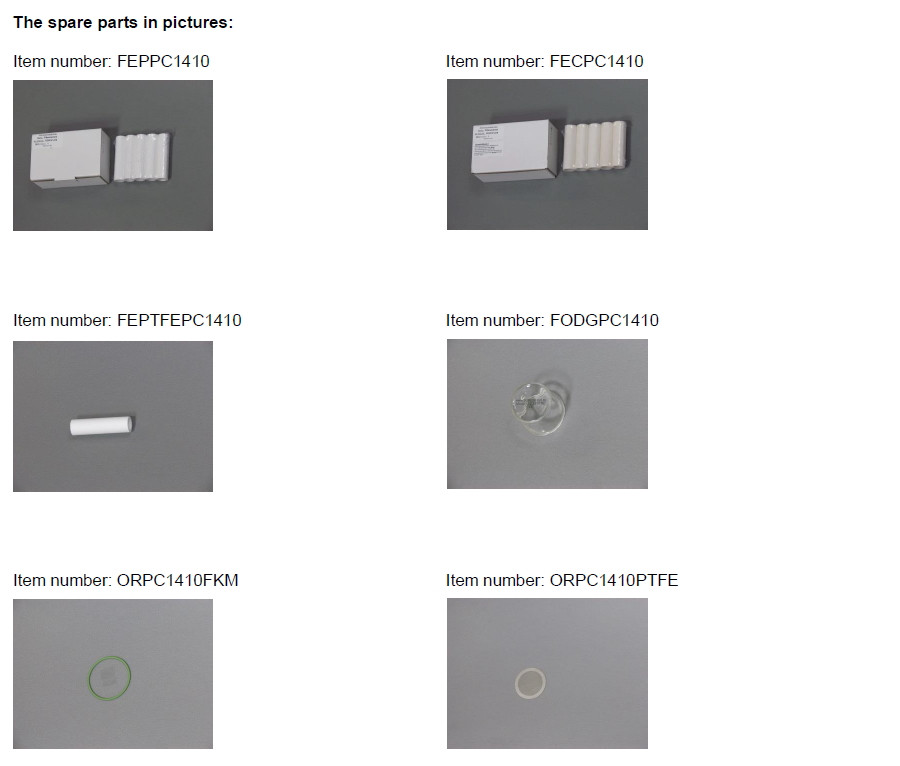

| Set (5 units) of filter elements for particle filtration, Material borosilicate micro glass fibres, pore size 0.1 μm, deposition rate 99.999% | FEPPC1410 |

| Set (5 units) of filter elements for coalescence application (removal of oils and aerosoles) and particle filtration. Material borosilicate micro glass fibres, pore size 0.1 μm, deposition rate 99.999% | FECPC1410 |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 1 μm | FEPTFE1PC1410 |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 10 μm | FEPTFE10PC1410 |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 25 μm | FEPTFE25PC1410 |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 50 μm | FEPTFE50PC1410 |

| 1 unit of filter element for particle filtration, Material PTFE-porous, pore size 100 μm | FEPTFE100PC1410 |

| 1 unit of blind plug PVDF, for locking the unused gas connection | VSPC1410PVDF |

| 1 unit of assembly bracket made of stainless steel 1.4571 for wall mounting | MONWIWAMOPC1410 |

| 1 unit of assembly bracket made of stainless steel 1.4571 for front panel installation | MONWIFROPPC1410 |

| Crash ring made of Plexiglas for Duran glass filter upper part | BSPC1410 |

|

Spare parts: |

|

| 1 unit of filter upper part made of Duran glass | FODGPC1410 |

| 1 unit of O-ring FKM (Viton) standard, color green | ORPC1410FKM |

| 1 unit of O-ring PTFE, color white | ORPC1410PTFE |

Note Blind plug: The PC 1410 model has 4 gas connections. If only two are used e.g. when using the particle filter (GAS-IN and GAS-OUT), two blind plugs will be required. If you additionally connect a bypass, only one blind plug is necessary in that case.

Please adhere to this in your next order.

PreviousPage (no previous) - NextPage (no next) - TOP