Water-Trap with extra fine particle filter

Water-Trap with extra fine particle filter

model WT 20.5

- Secure protection of the gas analyser from condensate and extra fine dust

- Low costs for reliable safety

- Made in Germany ![]()

![]()

- Certificates: ATEX 2014/34/EU, leakage tested

Functional description:

The Water-Trap is installed directly in front of the gas analyser in the piping. If the upstream gas processing (cooler, perestaltic pump, dust filter and the like) fails, the Water-Trap uses its semi-permeable SUN-C membrane® to protect the gas analyser.

The membrane separates gases from condensate and extra fine dust. If it is fully filled, the gas flow will be interrupted. An alarm is indicated via the upstream flowmeter with monitoring (refer to sample applications).

The Water-Trap is also known as a “Police filter”

Additional information from experience:

If the filter element, of the dust filter located in the gas processing is changed, particles are consistently dissolved and directed into the analyser. The downstream Water-Trap prevents this contamination as well with its diaphragm pore size of 0.1 μm.

Technical specifications:

| Scope of delivery: | Water-Trap, connection adapters (option), 2x assembly bracket for wall mounting (option) |

| Water pressure membrane: | 0 - 2 bar |

| Operating pressure for gas: | 0 - 2 bar |

| Gas flow: | 0 - 400 l air/h |

| Pressure drop at 100 l air/h: | approx. 10 mbar |

| Pressure drop at 400 l air/h: | approx. 40 mbar |

| Diaphragm pore size: | < 0,1μm |

| Operating temperature: | 0°C - +90°C |

| Effective filter area: | 25 cm2 |

| Housing volume: | 5 ml |

| Materials used: | PTFE, PP, assembly bracket made of stainless steel 1.4301 (option) |

| Dimensions: | Diameter 70 mm, length 120 mm |

| Gas connections: | on both sides 1/8“ NPT outside thread or on both sides 6 mm pipe nozzle or on both sides 6-12 mm stepped hose barb |

| Assembly: | Mounting in the existing piping or via mounting bracket (option) |

| Gas explosion proof ATEX: | EX II 2G Ex h IIB Gb -10°C ≤ Ta ≤ +90°C attestation EPS 19 ATEX 2 177 U |

| Helium leakage test: | 2 x 10-8 mbar I/s |

| Language operating instructions | German and English (included in the scope of delivery) |

| Spanish, Italian, French, Russian upon request | |

| Certificates/attestations: | certificate of conformity ATEX 2014/34/EU, Helium leakage test attestation |

For operation in potentially explosive ambience:

The products can be used in explosive ambience of Zone 1 and Zone 2. Allowed the explosion classes IIA and IIB.

The products have no self-heating during intended operation and can be used in dependency of the maximum permissible media temperature for gases of the temperature class T6.

Helium leakage test:

The product line has been subjected to a helium leak test. Single attestation on request.

Suitable for the following applications:

- Emission measurements with fossil fuels

- Renewable energy (Hydrogen technology)

- Biogases

- Ambient air monitoring

- Process measurement

- Heat treatments

- Cement, glass, steel, paper industries

- Combustion engines

Not suitable for the following applications:

Condensate with aromatic hydrocarbons, e.g. oils and fuels in refinery process gases. The models 20.82 E and the model 20.83 E XL with their oil-block membrane and coalescence filters have been designed for this.

Protection from dust:

The Water-Trap shows severe contamination of dust. The diaphragm with its pore size of 0.1 μm retains even the finest dusts.

Connection variation:

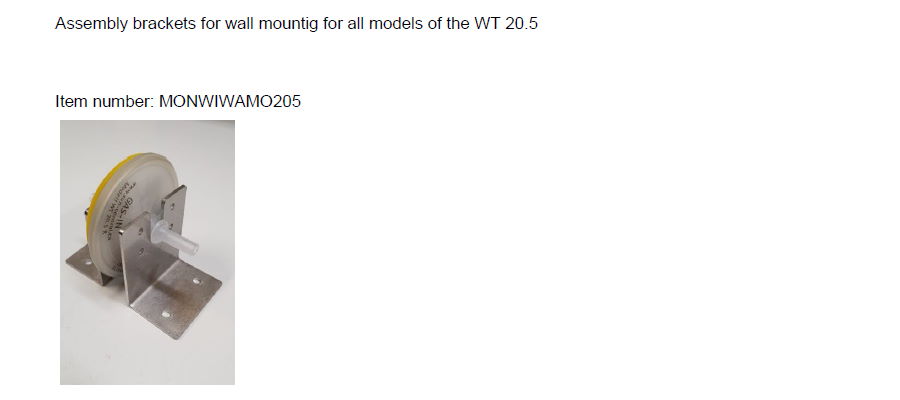

Option: Assembly brackets for wall mountig

protection of utility patents DE 20 2016 100 476

Article numbers:

| Item | Item number |

|---|---|

| Water-Trap WT 20.5 R, connections on both sides 6 mm nozzle | WT205R |

| 1 pair (2 units) connection adapter with 6 mm pipe connection for screwed hose connection 6/4 mm | VE6R64 |

| Water-Trap WT 20.5 N, connections on both sides 1/8” NPT outside thread | WT205N |

| 1 pair (2 units) connection adapter with 1/8” NPT threaded connection for screwed hose connection 6/4 mm | VE18N64 |

| Water-Trap WT 20.5 S, connections on both sides 6.1 mm-12.7 mm stepped hose barb | WT205S |

| Assembly brackets for wall mountig for all models of the WT 20.5 | MONWIWAMO205 |

Sample application 1: Flue gas analysis

Advantage:

The analyser is protected in case of failure of the cooling system (cooler, perestaltic pump). Another Water-Trap can be used for protecting the gas processing.

Sample application 2: Strip systems

Advantage:

In case of a clogged flow, the HC-FID is protected from harmful water.

PreviousPage (no previous) - NextPage (no next) - TOP