Water-Oil-Trap with extra fine particle filter

Water-Oil-Trap with extra fine particle filter

model WT 30.5 E in a stainless steel housing

- With Dual-Membrane-System® to stop of water, acid, alkali, liquid hydrocarbons and extra fine dust

- Bypass integrated

- Minimum gas volume of just 2 ml

- Especially für gas-chromatographsn

- “Easy Change System” of the inner diaphragm After removing the cover screws, the diaphragm can be replaced quickly and effortlessly. It is not necessary to remove the screw connections

-All gas connections on the lower part of the housing

- Made in Germany ![]()

![]()

![]()

- Certificates: 3.1 material quality certificate, ATEX 2014/34/EU, Helium leakage tested

Functional description:

The Water-Oil-Trap is used as a protection of gas analysers from liquids (Water, acid, alkali, liquid hydrocarbons)and particles. A bypass connection is integrated.

The Water-Oil-Trap is installed directly in front of the gas analyser in the tubing. If the upstream gas processing (cooler, peristaltic pump, dust filter and the like) fails, the Water-Oil-Trap uses its semi-permeable membrane with SUN-C Dual Membrane System® to protect the gas analyser. The membrane separates gases from condensate and extra fine dust. The Water-Oil-Trap is designed as a bypass filter. The main gas flow can be discharged again via the bypass; a partial current (1:2 to 1:20) will be provided to the analyser. This results in quick response times of the analyser. Condensate carried along is also discharged via the bypass. The aligned incoming flow of the membrane has another additional self-cleaning effect. An alarm is indicated via the upstream variable area flowmeter with monitoring (customer side).

The Water-Oil-Trap is also known as a “Police filter”.

Schematic representation:

Technical specifications:

| Scope of delivery: | Housing complete with membrane, filter and, wall assembly bracket |

| Water pressure membrane: | 0 - 2,0 bar with DMS (Dual-Membrane-System®) |

| Oil pressure (10W40) membrane: | 0 – 0,3 bar with DMS (Dual-Membrane-System®) |

| Gasoline (ROZ 95) Membrane: | 0 – 0,2 bar with DMS (Dual-Membrane-System®) |

| The Dual-Membrane-System® of the Water-Oil-Traps is a novel membrane system. Condensates such as water, acid, alkali and liquid hydrocarbons, for example, oils and gasolines in refinery process gases are retained. | |

| The design is subject to a legal protection of registered designs (registered number 20 2016 100 476) | |

| Operating pressure for gas: | 0 - 50 bar (higher pressures on request) |

| Gas flow: | 0 - 60 l air/h |

| Pressure drop at 15 l air/h: | approx. 30 mbar |

| Pressure drop at 30 l air/h: | approx. 60 mbar |

| Pressure drop at 60 l air/h: | approx. 130 mbar |

| Diaphragm pore size: | < 0,1μm |

| Operating temperature: | - 20°C - +190°C |

| Effective filter area: | 12 cm2 |

| Housing volume: | 2 ml |

| Materials used: | Stainless steel type 1.4571, FKM (Viton), PTFE |

| Wall mounting bracket (option): | Stainless steel type 1.4301 |

| Housing dimensions: | Diameter 60 mm, height 60 mm, Depth 100 mm (incl. mounting bracket) |

| Gas connections: | GAS-IN 1/8“ NPT inside thread BYPASS 1/8“ NPT inside thread GAS-OUT 1/8“ NPT inside thread |

| Assembly: | Wall mounting with assembly bracket (included in scope of delivery) |

| Assembly advice: | Installation of the bypass is recommended. Consider the max.membrane pressures if no bypass is possible |

| Gas explosion proof ATEX: | EX II 2G Ex h IIC Gb -20°C ≤ Ta ≤ +190°C attestation EPS 19 ATEX 2 178 U |

| Dust explosion proof ATEX: | EX II 2D Ex h IIC Gb -20°C ≤ Ta ≤ +190°C attestation EPS 19 ATEX 2 178 U |

| Helium leakage test: | 2 x 10-7 mbar I/s |

| Language operating instructions: | German and English (included in the scope of delivery) |

| Spanish, Italian, French, Russian upon request | |

| Certificates/attestations: | 3.1 material quality certificate, NACE-MR0175-98, ATEX 2014/34/EU, Helium leakage test attestation |

For operation in potentially explosive ambience:

The products can be used in explosive ambience of Zone 1, Zone 2, Zone 21 und 22.

Allowed the explosion classes IIA, IIB und IIC.

The products have no self-heating during intended operation and can be used in dependency of the maximum

permissible media temperature for gases of the temperature class T6.

Helium leakage test:

The product line has been subjected to a helium leak test. Single attestation on request

SUNOX100-process

Oil and grease-free products for applications with 100% oxygen (on request)

protection of utility patents DE 20 2016 100 476

Article numbers:

| Article | Item number |

|---|---|

| Water-Oil-Trap WT 30.5 E Material stainless steel 1.4571 (316 Ti), as per technical specifications. O-rings FKM (standard) | WT305E |

| Water-Oil-Trap WT 30.5 E Material stainless steel 1.4571 (316 Ti), as per technical specifications. O-rings PTFE | WT305EORPTFE |

| Water-Oil-Trap WT 30.5 E Material stainless steel 1.4571 (316 Ti), as per technical specifications. O-rings FFKM | WT305EORFFKM |

| Option: | |

| 1 unit of assembly adapter for front panel assembly, Material plastic (PTFE) | ADAPFROP305 |

|

Spare parts: |

|

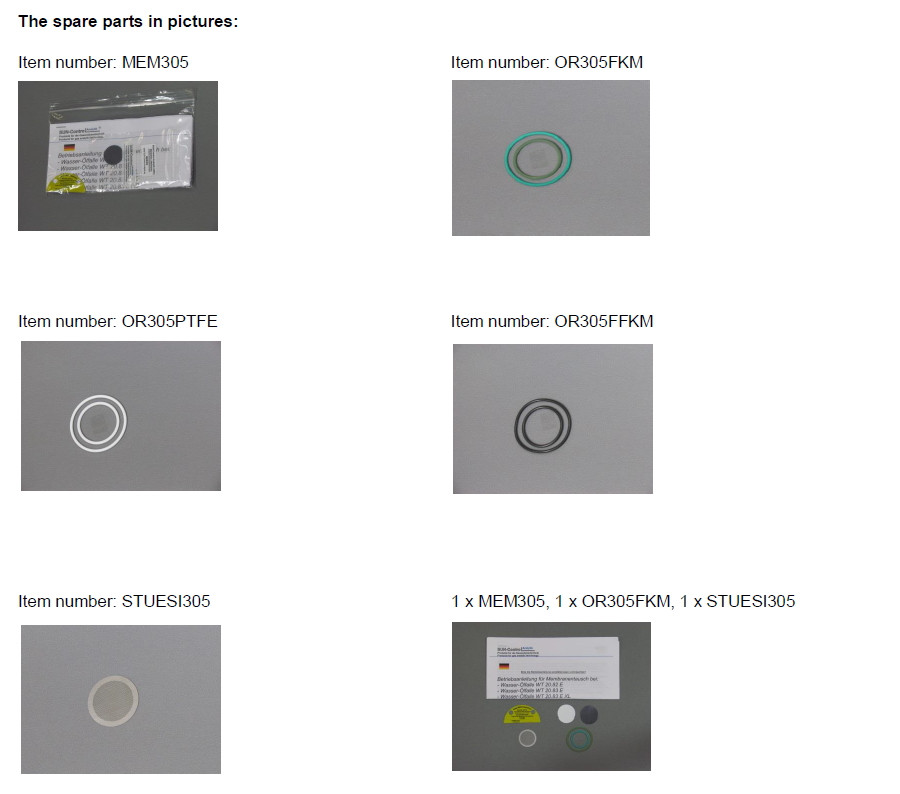

| Spare membrane, including white membrane, grey membrane and indicator plate | MEM305 |

| Set of O-rings FKM Viton (standard) color green | OR305FKM |

| Set of O-rings PTFE, color white | OR305PTFE |

| Set of O-rings FFKM, color black | OR305FFKM |

| Supporting sieve | STUESI305 |

| Spare parts kit 1, including: 1 x MEM305, 1 x OR305FKM, 1 x STUESI305 |

ET1PA305 |

Note:

-The standard product is equipped with FKM O-rings. For additional information about O-rings, refer to “Informations”.

-PTFE O-rings for single use only

Sample application for flue gas analysis with bypass:

PreviousPage (no previous) - NextPage (no next) - TOP